SAURER Technologies GmbH & Co. KG Twisting Solutions is the global market leader in twisting machines for glass yarn and basalt filament. The GlassTwister is an innovative high performance ring twisting machine for winding up glass filament as well as plied yarns that has well established itself on the market. Our twisting systems provide an optimal level of flexibility in the production of glass and basalt filament yarns.

Along with a range of services oriented toward customer needs, there is an attractive comprehensive package available – from project planning to the service warranty and original part availability spanning all machine generations. Moreover, SAURER is the sole supplier of the original parts for twisting

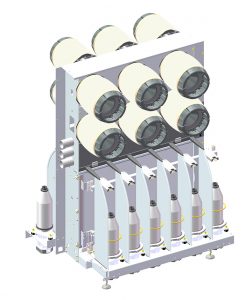

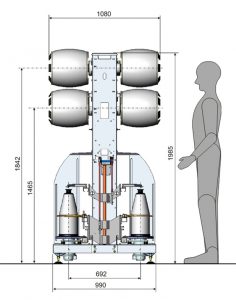

GlassTwister – innovative high-performance ring twisting machine for winding up and twisting of glass and basalt filament yarns.

The key advantage of VGT machine is the perfect yarn packages produced on our machine. The optical appearance of the packages is impressive, but more important is an excellent further downstream processing of the yarn (e.g. on weaving machines) thanks to the outstanding quality of supply package achieved by the precisely controlled ring rail motion.

In addition to the highly developed and state-of-the-art technology, GlassTwsters offer many advantages with regard to efficiency and economy:

- Full motorisation of the machine – from individual drive of creel baskets to individual motorspindles – allows achieving the highest precision as well as guarantees very low spare parts consumption (tangential belt drives which are usually a subject of high wear and tear do not exist in the GlassTwisters).

- The spindles, which are usually operated under high loads, are designed in way that can be re-greased during operation without stopping the machine, it means without any production losses.

- Non-slipping synchronous drives of the individual creel baskets ensure equal running lengths of the yarn packages over entire machine.

- The modular design and the tested preassembly at the manufacturer’s factory allows reducing the installation time and costs.

- Flexibility in terms of production of all kinds and shapes of packages.

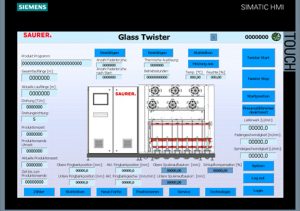

- Data input and monitoring of process parameters and production data. Setting all parameters on IPC with touch-screen (creel basket speed, spindle speed and twist level, ring rail speed, package shape building, defining yarn length per spindle (optional), temperature, air volume, etc. for hot-air drying system (optional)).

To resume the advantages of GlassTwisters, the customer gets high productivity, flexibility and reliability with low energy consumption, low noise level, low maintenance costs.

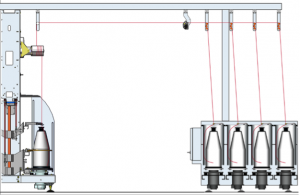

GlassTwister VGT-11-P – multiply ring twisting machine with integrated plying unit.

The integrated plying unit is most suited for the production of balanced multi-ply glass yarns.

- GlassTwister basic machine is extended on each side with the pre-twisting system. Pre-twisting system is equipped with individual motorspindles as well for the highest precision and reliability. Replacing the spinning cakes baskets with delivery capstans allows the production of 2 to 4-ply twisted yarns (in case of operating every second take-up spindle – up to 6 or 8-ply twisted yarns).

- The flexible system is also suitable for other fibres such as: Basalt, PA, PET, CV, Aramid, PVA, Dyneema, PE/PP as multi- and monofilament yarns. The new machine generation VGT11-P opens unlimited fields to the production of high performance multi-ply filament yarns.

For more information please visit https://saurer.com/en/products/machines/twisting-and-cabling/glass/glasstwister or contact us: click here