Carpet yarn (BCF) solutions by Trützschler are based on comprehensive know-how combining high quality of yarn with flexible and cost-effective operation.

SymTTex BCF systems covers a broad range of applications:

- Mono-colour yarns for woven and tufted carpets

- Tri-colour yarns for tufted carpets

- Spun-dyed yarns and high-requirements yarns for automotive application

SymTTex BCF solutions are highly flexible and are available optionally with 2, 3 or 4 ends per spinning position, depending on customer’s requirements (like available space, yarn characteristics, productivity). Polymers that can be process with symTTex lines include PA6, PET, R-PET, PP. All lines are equipped with the central computerized control system giving an overview and monitoring possibility of all status and settings.

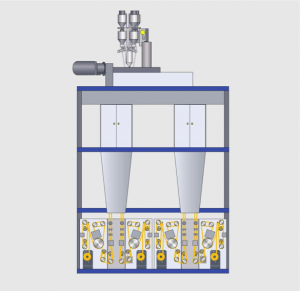

M20/T20 – the 2-end M20 (mono-colour yarn version) is characterized by its compact design. Due to low installation height and mirroring of spinning positions, string-up is easy and quick. This increases efficiency and minimizes downtime and waste. T20 is a tri-colour yarn version containing the same advantages as M20. Optionally, the patented FLEX technology or the newly developed ecoFLEX solution is available for tri-colour T20 systems. A special arrangement of texturing and intermingling jets allows the inline creation of the most versatile yarn effects.

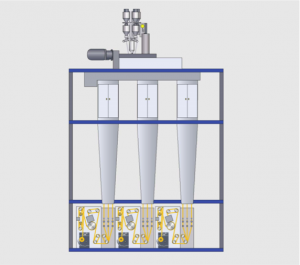

M30 – The 3-end solution M30 answers customer needs concerning both productivity and economic efficiency. With 3 bobbins on the winder it is similar compact-build as M20 but delivers a significantly higher productivity. On the other hand, productivity is lower than M40, but handling one winder per spinning position is easier than the solution of two winders per position. M30 features all proven solutions like top-loading rectangular spin packs, HPc texturing unit, DSR double shell godets, ergonomic winder design.

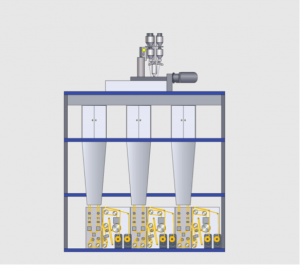

M40 – The solution of 4-ends is usually chosen for highest productivity. The keyword for the M40 is symmetry. The machine is characterized by the symmetrical arrangement of the spinning positions which allow a very straight yarn path with only a few friction points. The component arrangement in the draw panel results in a longer drafting zone; thus, it is also optimal for processing sensible materials such as polyester. Every symTTex M40 system is equipped with the highly efficient HPc texturing unit as well as two 2-end winders.

Be confident before investing – testing in our technical centre is possible. For customers who want to experience our competence in actual practice, we offer a very special opportunity: a visit to our technical centre in Winterthur with testing facilities for BCF and industrial yarns. There you can benefit by implementing new product ideas, validating the entire process chain at production level from polymer to yarn. These tests also ensure that the production line can meet all current and future market requirements.

For more information please visit https://www.truetzschler-manmadefibers.de or contact us: click here